jjsararas

New member

- Joined

- Sep 25, 2019

- Messages

- 12

- Reaction score

- 0

- Points

- 1

- Excel Version(s)

- 2016, 365

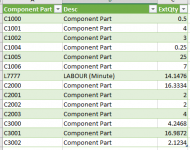

I'm looking for some ideas to deal with nested BOM structures, and how to get forecast quantities to flow through properly. I have a finished product- the X10000, which is made of components, and some of the components also have structures of their own. So effectively, a 'Component' at one level, is a 'Parent' at the next level, and so on. This nesting goes 3 levels deep. The trick is my table in the database is only 4 columns: Parent, Component, Qty, Desc, with the same SKU appearing in multiple places at multiple levels. I need to apply a forecast quantity for the finished product (The X10000), and have it flow through and apply the multiplier through all components in order to plan resources. I've attached an Example.xlsx laying out my db table structure along with a visual representation of the 'actual' nested structure. Thanks in advance!